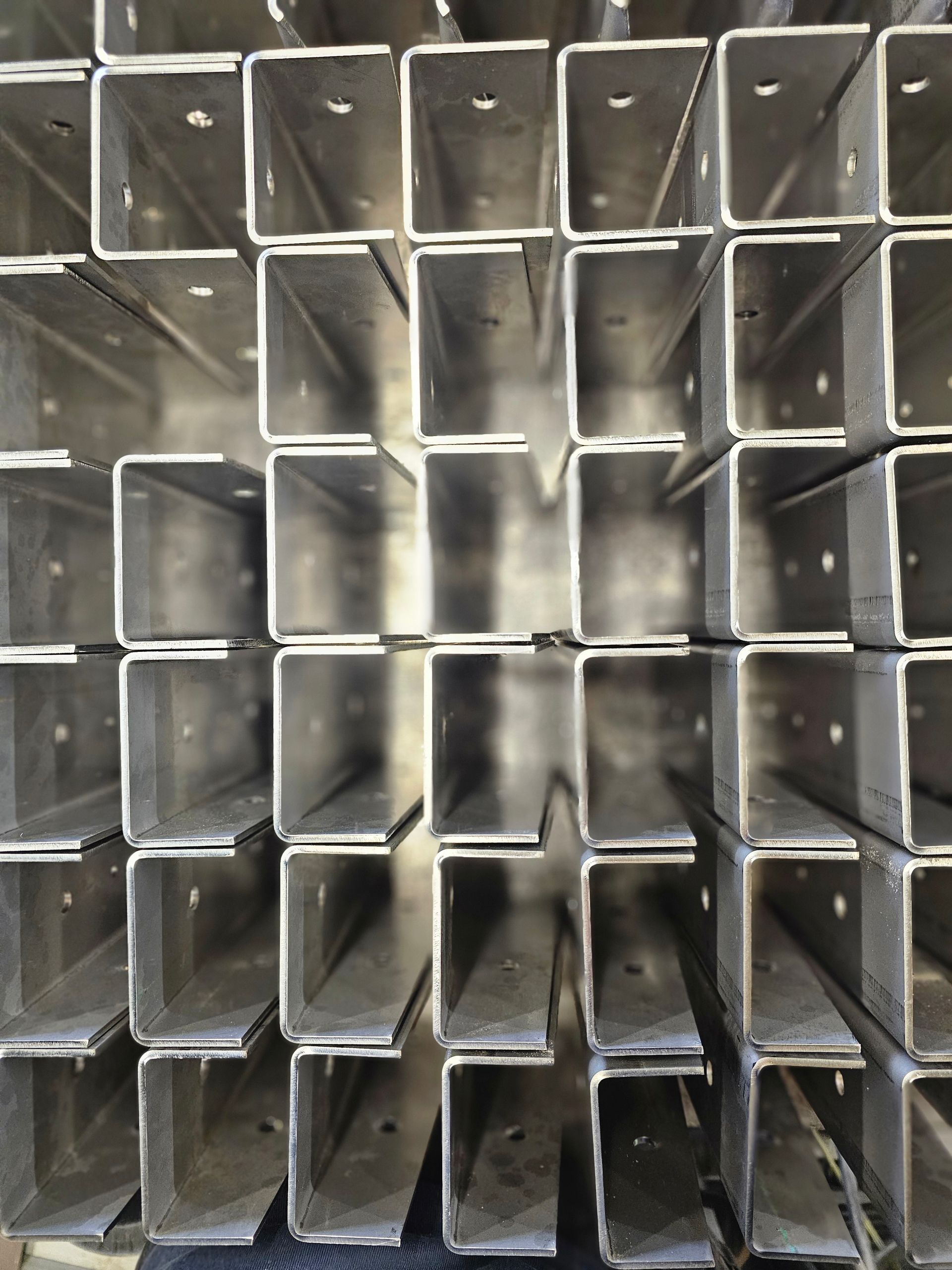

Sheet Metal Folding & Precision Cnc Bending

streamlined service

Delivering high quality

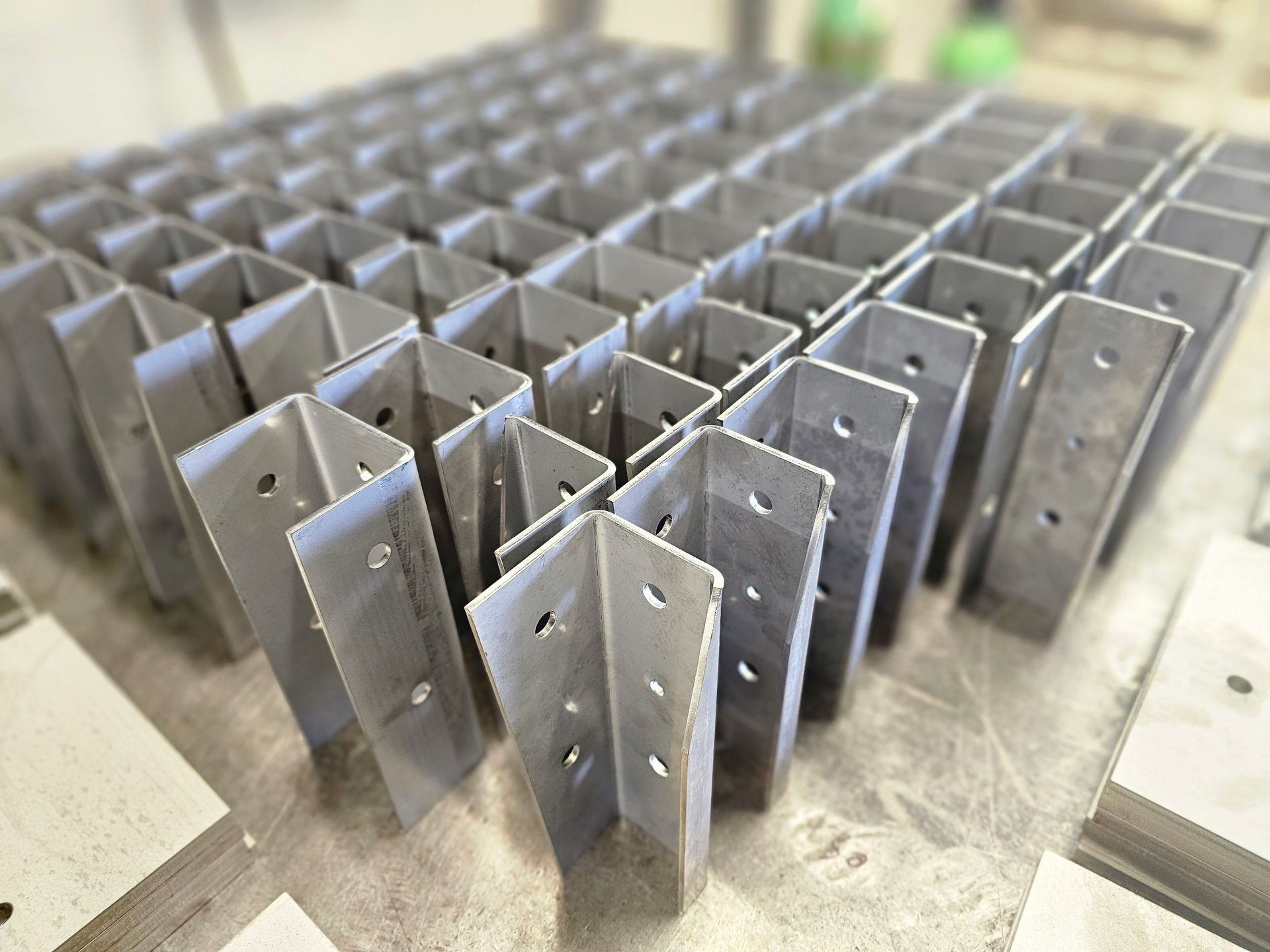

Our sheet metal folding and precision bending services are designed to deliver high quality, accurate results for your custom metal projects. We can fold and bend metal with incredible precision, ensuring that each component fits perfectly within your specifications.

design to completion

Precision. Quality. Reliability

From the initial design phase, where we collaborate with you to create detailed CAD drawings, to selecting the right material for the job, we handle every aspect with care. Our process includes advanced simulation in our software to optimise each bend and minimise any risk of errors. With our expertise, we can fold and bend metal to the tightest tolerances, whether you're creating complex parts or simple, functional components.

inspection process

Cost Effective Solution

Once the bending is complete, we carry out thorough inspections to ensure the final product meets the highest standards of quality. Whether it’s a single piece or a large batch, our sheet metal folding and bending services deliver reliable, cost effective solutions.

OUR CAPABILITIES

Capabilities

Our in-house folding capabilities include:

• Mild Steel: Up to 2.5 meters in length and 2.5mm thick.

• Stainless Steel: Up to 2.5 meters in length and 1.6mm thick.

• Aluminium: Up to 2.5 meters in length and 3mm thick

metal folding capacity

Reliable Folding Solutions

In addition to our in-house folding services, we work closely with trusted partners, allowing us to offer CNC press brake services with a maximum folding length of 4 meters and a material thickness of up to 20mm. This extended capacity ensures we can handle even the most demanding steel folding projects with precision and efficiency.

delivering solutions

Precise & Consistent

Whether working with thin, flexible materials or thick, durable metals, we ensure precise and consistent results. From complex angles to tight radii and large scale fabrications, our experienced team combines advanced technology with expert craftsmanship to deliver solutions that meet your exact specifications and exceed expectations.

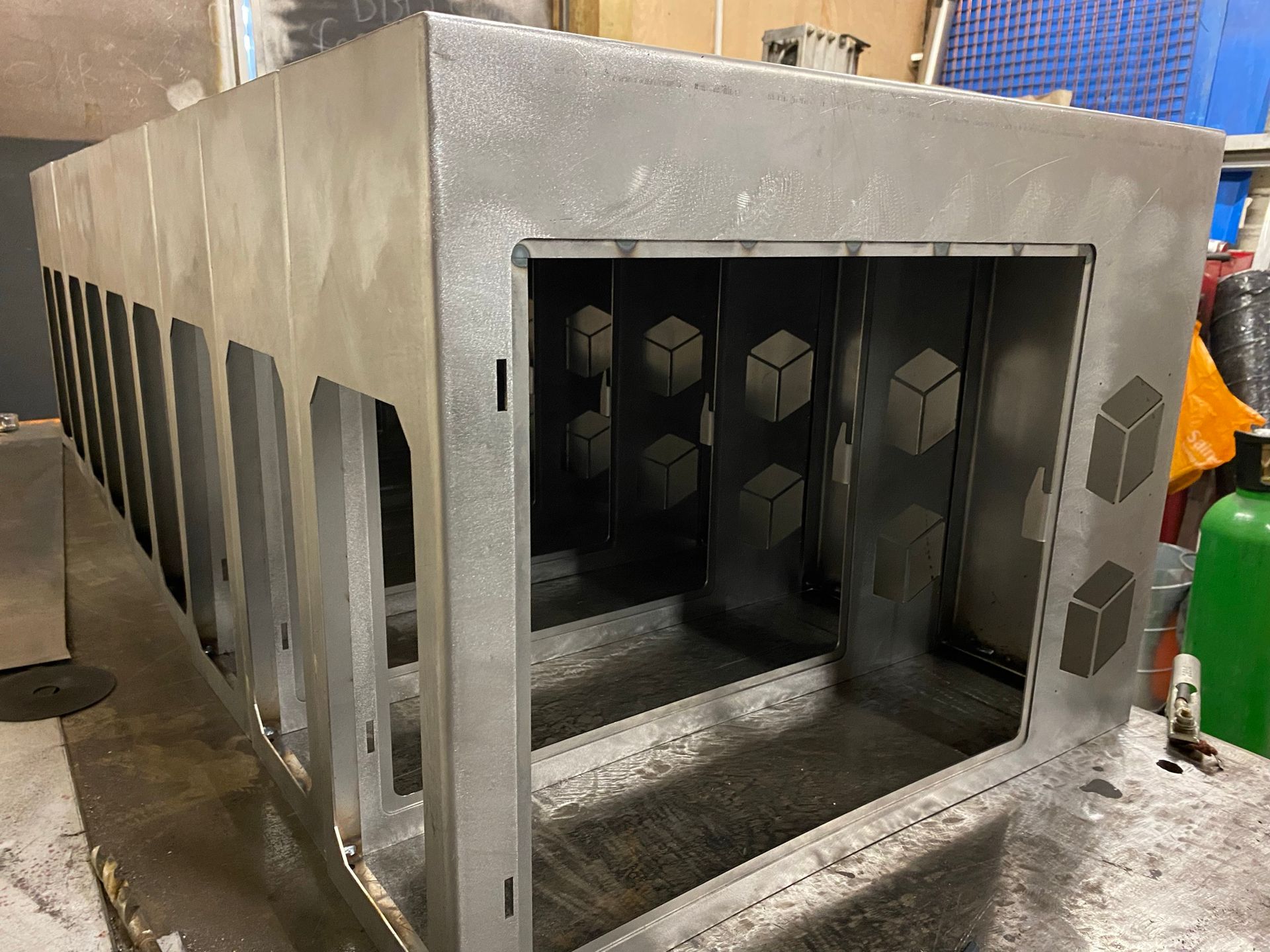

Complex Forming

CNC press braking is the ideal choice for complex forming tasks, offering unparalleled precision and consistency across a wide range of shapes and angles. With its advanced technology, CNC press brakes can execute intricate bends with exact accuracy, ensuring that even the most detailed designs are perfectly formed.

More Environmental

An environmentally friendly choice, as it minimises material waste and enhances energy efficiency throughout the forming process. By utilising precise, computer controlled bending, CNC press brakes reduce the need for rework and scrap, ensuring that more of the raw material is used effectively.

Versatility

Offering exceptional versatility, making it ideal for a wide range of metal forming applications. Whether you need simple bends or complex, multi-axis shapes, CNC technology can handle it all with precision and flexibility.

Accurate Results

Delivering highly accurate results, ensuring that every bend is executed with exceptional precision. The advanced computer controlled system allows for tight tolerances and consistent repeatability, making it ideal for complex designs that demand flawless execution.

Advantages

Why choose CNC press braking?

Choose CNC press braking for its unmatched precision, efficiency, and ability to handle complex bends with consistent, high-quality results

FAQs

Everything you need to know about sheet metal folding

Have a look at our frequently asked questions. If you can’t find the answer you are looking for, then get in touch, and a team member will be on hand to help you with any questions you might have. Call us on 01684 210 610 or send us an email.

What is sheet metal folding and precision bending?

Sheet metal folding and precision bending involve shaping flat metal sheets into specific angles and forms using specialised equipment. This process is used to create accurate, custom metal components for various applications.

What types of metals can you work with?

We work with a wide range of metals, including steel, stainless steel, aluminum, and brass. If you have specific material requirements, let us know, and we'll ensure the right metal is used for your project.

What is the maximum thickness you can bend?

We can handle metal sheets of various thicknesses, from light gauge to heavy duty sheets up to 10mm thick, depending on the material type and project requirements.

Can you produce custom parts with complex shapes?

Yes, we specialise in creating custom parts with complex shapes and angles. Our precision bending equipment allows us to meet exact specifications and produce high quality, tailored components.

How quickly can I receive my order?

Lead times depend on the size and complexity of your order. We aim to provide quick turnaround times while maintaining high standards. Contact us for an estimated delivery time based on your specific project needs.

Do you offer prototype or small batch production for sheet metal parts?

Yes, we offer both prototype and small batch production services. Whether you need a single part for testing or a limited run of components, we can accommodate your needs with precision and quick turnaround times.

OUR SERVICES

See what else we do

We have a wide range of metal fabrication services available for your business needs. Please take a look at the other services we have available.

GET IN TOUCH

Request a free quote

To learn more about our services and get a bespoke quote, please don’t hesitate to contact the team on 01684 210 610 or click the button below.