CAD Design Services

expert cad services

CAD Design

Services at Perfect Fabrications

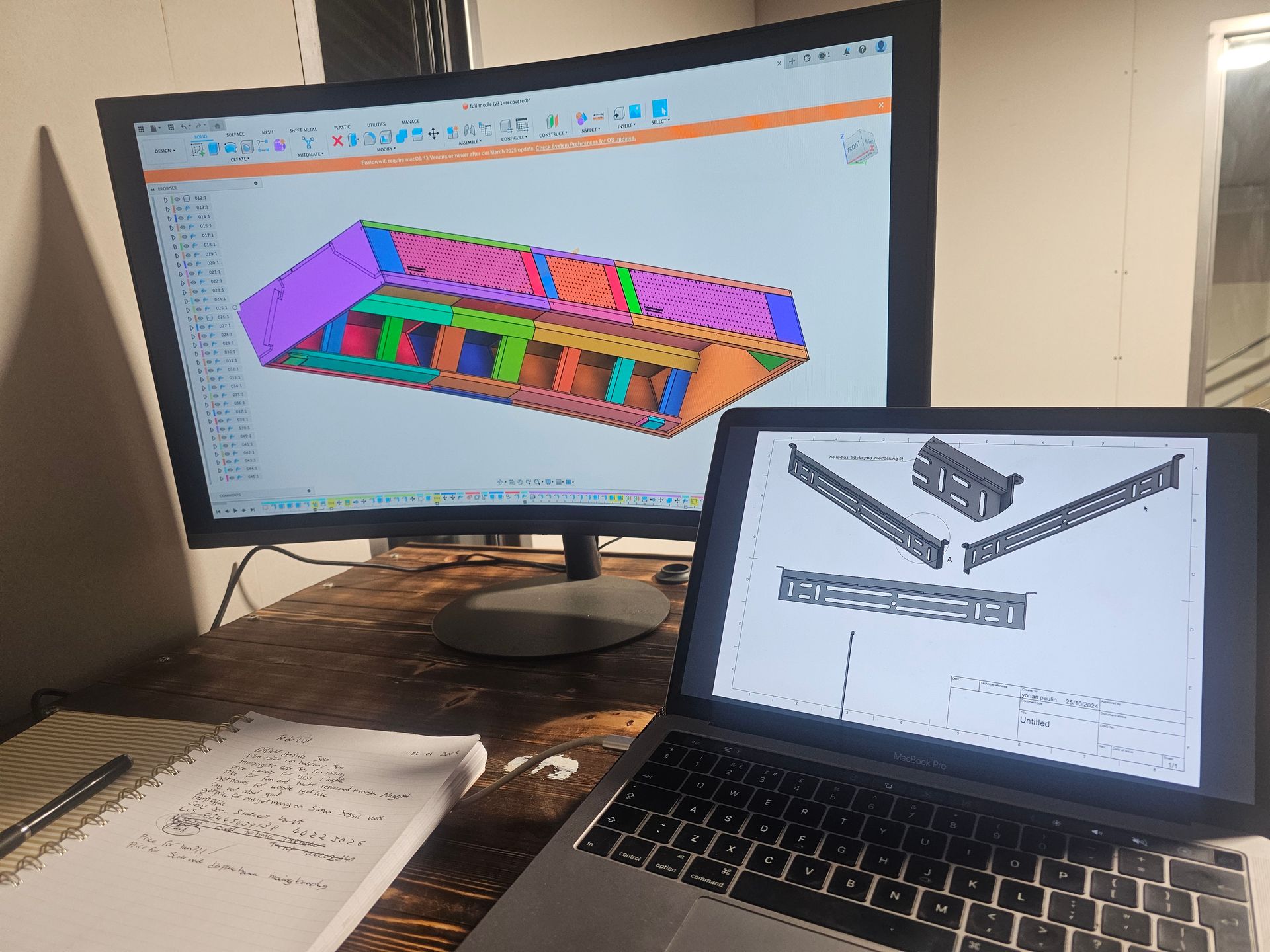

At Perfect Fabrications, we offer versatile CAD services tailored to your needs—whether as a standalone service or as part of a complete fabrication project. Our CAD expertise is ideal for developing new products, creating prototypes, or refining existing designs.

We collaborate closely with our customers, allowing you to be fully involved in the design process. Visit our office to watch your project take shape in real time and make live adjustments, or opt for the convenience of a Zoom call for remote collaboration. Using Fusion 360, we create detailed technical drawings, flat patterns, DXF files, and fully realized 3D models to ensure every component is designed with precision and ready for production.

Partner with us to bring your ideas to life with expert CAD solutions!

detailed planning

How Our CAD Services Benefit You

Our CAD services help customers to make informed decisions by visualizing their 3D parts in real time. This capability offers significant advantages, including reducing errors during the fabrication process by identifying and addressing potential issues early on. By optimizing designs and minimizing material wastage, we help keep costs down, making your project more economical. Additionally, we design parts in ways that dramatically reduce fabrication time, further lowering costs and speeding up project completion.

For prototyping, our CAD work and 3D modeling are invaluable tools. Customers can see how parts function together in a dynamic, moving model, allowing adjustments and refinements before production begins. This ensures the final product not only meets your expectations but performs seamlessly, saving time, resources, and effort in the long run.

cost effective solution

Our CAD Process

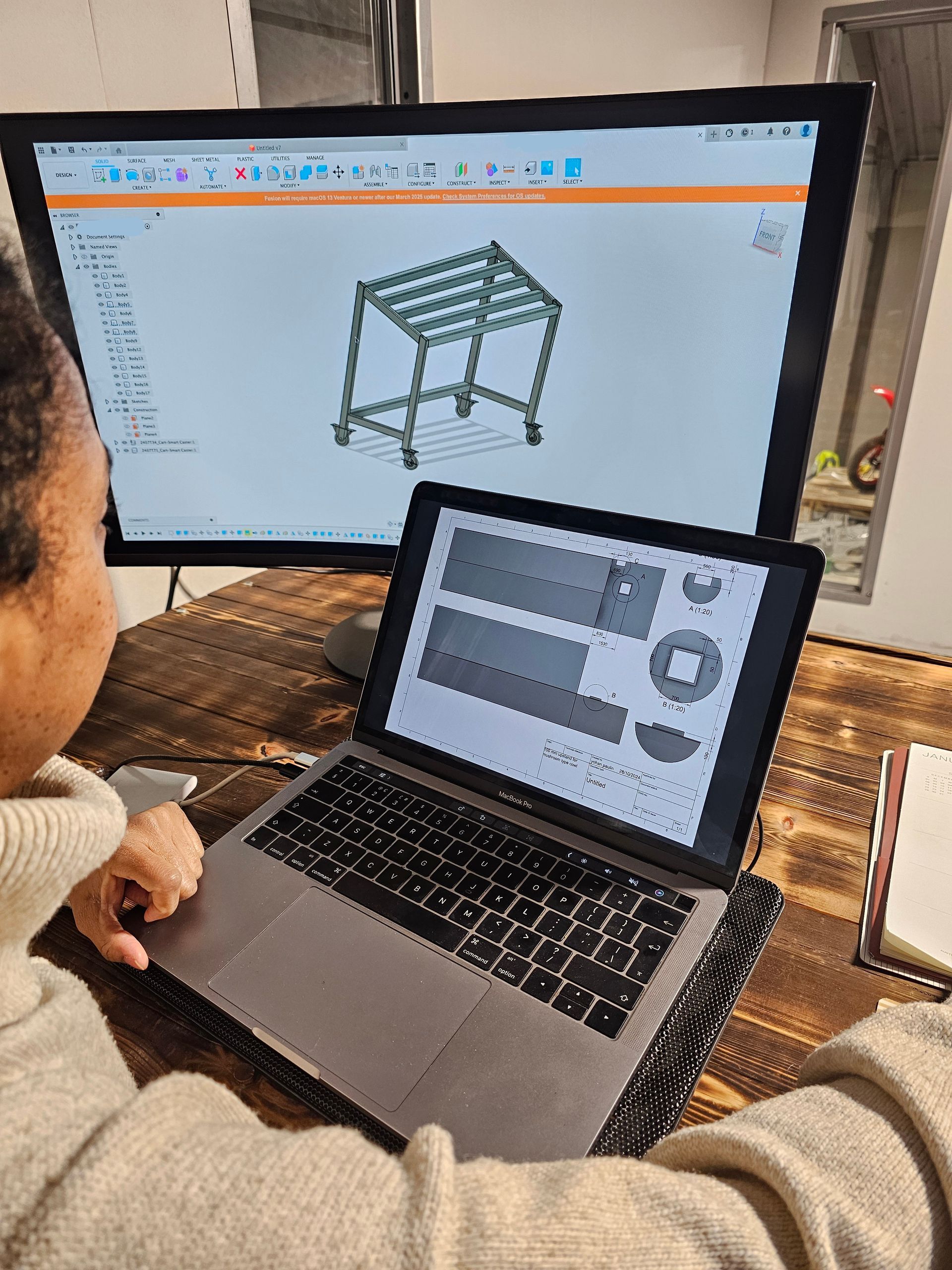

Whether you’re opting for a CAD-only service or need a 3D model for a prototype project, our process is designed to ensure your vision is fully realized:

1.

Free Consultation:

We start with a 30 minute consultation at our office to understand your needs and create a rough model of your project. This initial session helps us clarify your requirements and ensure we’re on the same page.

2.

Collaboration and Feedback:

Once the initial model is created, you’ll have the opportunity to suggest changes. You can visit us again to review updates or opt for a Zoom meeting to collaborate remotely. We continue refining the design until you’re completely satisfied.

3.

Finalizing the Design:

After the model is approved, we provide all the necessary technical drawings and 3D models for your use. Alternatively, if you’d like to move forward with production, we can seamlessly transition the project into the fabrication phase.

Our CAD process is built around flexibility and customer input, ensuring the final design meets your exact specifications.

cad software

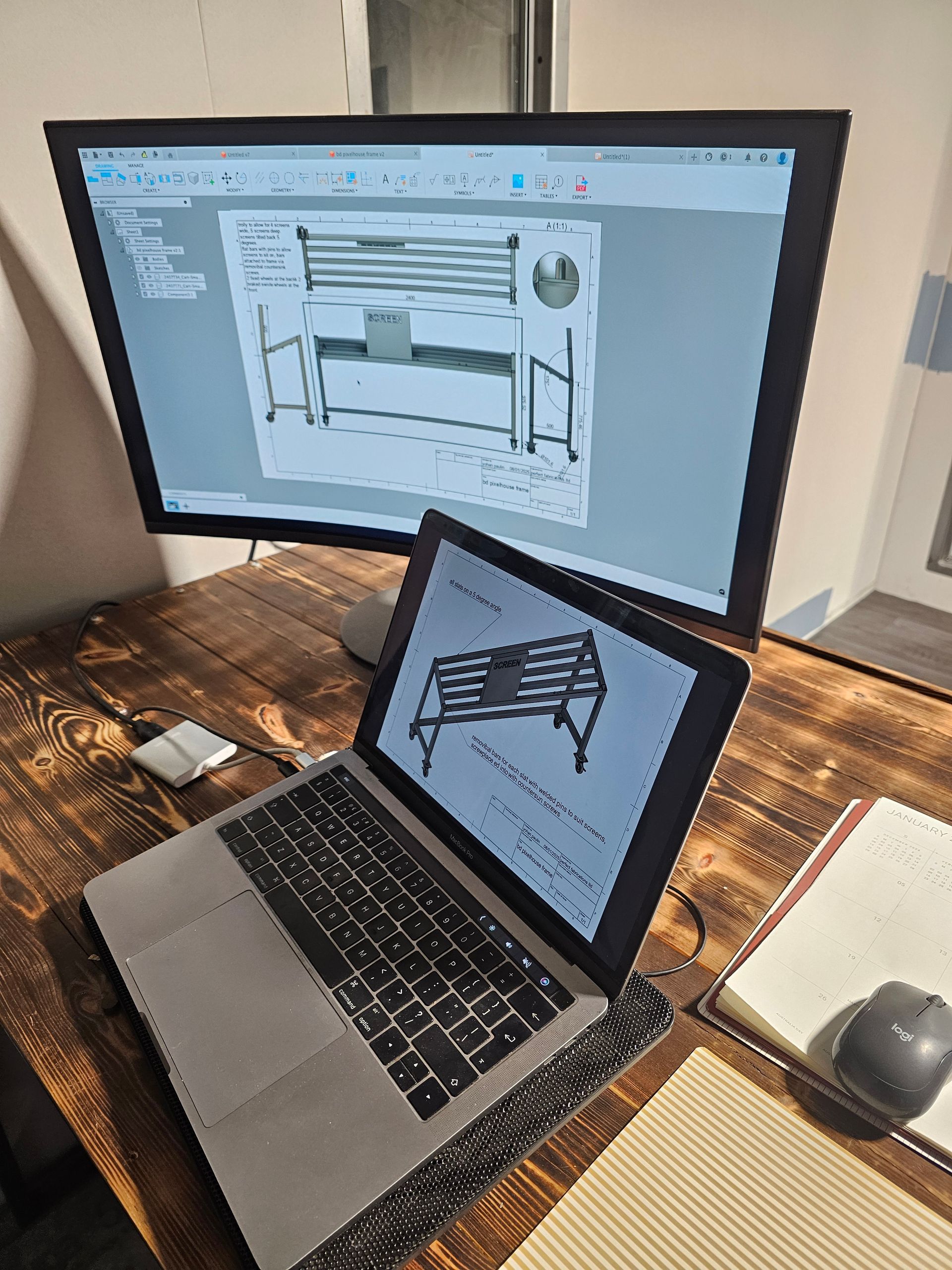

What Is Fusion 360

Fusion 360 is an all-in-one design software that empowers fabrication companies to create both 2D and 3D models with ease. With its powerful tools for sketching, modeling, and assembly design, it enables precise and efficient development of complex parts. The software also integrates CAD and CAM, allowing seamless transition from design to manufacturing, whether for CNC machining, 3D printing, or other fabrication methods. Fusion 360's cloud-based platform fosters real-time collaboration, streamlining communication between teams and improving workflow efficiency.

By offering simulation and analysis capabilities, Fusion 360 helps fabrication companies ensure their designs are not only manufacturable but also structurally sound. With customizable features and automation tools, it enhances productivity and reduces the time spent on repetitive tasks, making it an invaluable asset for any fabrication business looking to optimize its design and production processes.

cam software

What Is CAM

CAM (Computer-Aided Manufacturing) software is a type of technology used to control and automate the manufacturing process. It takes digital designs created in CAD (Computer-Aided Design) software and converts them into machine-readable instructions that control CNC (Computer Numerical Control) machines, 3D printers, and other manufacturing equipment. CAM software helps optimize machining processes by generating toolpaths, selecting cutting tools, and defining parameters like speed, feed rates, and material removal strategies. This ensures that parts are produced with high precision and efficiency, reducing the risk of errors and improving overall production speed. CAM software plays a crucial role in modern manufacturing by bridging the gap between digital design and physical production.

Visualisation

CAD allows for unparalleled visualisation, giving you the ability to see your designs in stunning detail before any physical work begins.

Detail & Accuracy

With 3D modeling, you can explore every angle, test functionality, and make real time adjustments, ensuring that the final result aligns perfectly with your vision.

Cost effective

This level of clarity reduces uncertainty, enhances decision making, and helps avoid costly revisions, ultimately leading to a more streamlined and successful project.

Computer Aided Manufacturing

Whether it’s a product, space, or system, CAD empowers you to bring your ideas to life with confidence.

Advantages

Why use CAD?

The Power of CAD for Smarter, Faster Design

FAQs

Everything you need to know about CAD

Have a look at our frequently asked questions. If you can’t find the answer you are looking for, then get in touch, and a team member will be on hand to help you with any questions you might have. Call us on 01684 210 610 or send us an email.

What is CAD design (Computer-Aided Design)?

CAD (Computer-Aided Design) is a technology used to create detailed, precise 2D and 3D models of physical objects or structures. It allows engineers, designers, and fabricators to visualize, modify, and analyze designs digitally before production begins. By using specialized software, CAD makes it easier to create complex geometries, test functionalities, and generate technical drawings, all with a high level of accuracy.

CAD is essential in many industries, including manufacturing, engineering, architecture, and prototyping, as it helps streamline the design process, reduces errors, and improves the overall efficiency of production. Whether you need to design a single part or an entire assembly, CAD is a powerful tool that turns ideas into reliable, production-ready designs.

What types of projects can you create with CAD design?

Our CAD design services cover a wide range of projects, including custom metalwork, structural components, brackets, and bespoke fabrications. Whether it's a small part or a large scale project, we can provide detailed, accurate designs tailored to your specifications.

Can you work from my sketches or existing designs?

Absolutely! We can take your sketches, measurements, or existing designs and transform them into precise CAD models. This allows us to make any necessary adjustments and provide you with a digital representation of the final product for approval before fabrication.

How long does the CAD design process take?

The time required for CAD design varies depending on the complexity of the project. For smaller designs, it may take just a few days, while more intricate or large scale projects could take longer. We will provide an estimated timeline after discussing your requirements.

Can I make changes to the design during the process?

Yes, you can! We encourage client feedback throughout the CAD design process. If you need to make adjustments, we will work with you to refine the design until it meets your expectations before moving on to fabrication.

OUR SERVICES

See what else we do

We have a wide range of metal fabrication services available for your business needs. Please take a look at the other services we have available.

GET IN TOUCH

Request a free quote

To learn more about our services and get a bespoke quote, please don’t hesitate to contact the team on 01684 210 610 or click the button below.